Blackfasts’ room temperature blacking process is a simple dip operation specifically designed for use in factories. The process does not materially effect dimensions and a uniform colouring is obtained over machined surfaces, threads and blind holes. Blacking is achieved by chemical conversion of the metal surface and the process entails degreasing, immersion in a surface conditioner, and blacking solution. Corrosion protection is afforded by a final immersion in a dewatering oil.

The solutions are designed to be ‘topped up’ with neat chemicals when the solutions become weak through use.

Disposal of solutions usually only occurs where the tanks have been contaminated.

STEP ONE: Light Alkaline Degreaser (Diluted 50%) Operating at 20OC.

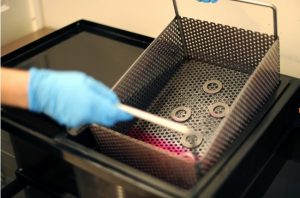

. Load the basket or Jig with components and place in tank

. If components are in a basket agitate periodically to ensure even contact with solution.

. Leave for between 15-40 minutes until clean.

. Lift out basket or jig and place into rinse water immediately to eliminate flash drying of components.

STEP TWO: Water Rinse: Immerse in rinse tank ensuring water flow is adequate and with good air agitation.

STEP THREE: Conditioner ( Diluted 10%).

. Place basket or jig in tank.

. Soak components for 30 seconds to 1 minute

. If components are in a basket agitate periodically to ensure even contact with solution.

. Lift out basket or jig and gently shake of excess solution DO NOT AIR BLAST. Keep a wet surface.

. Place basket or jig into tank four.

STEP FOUR: Water Rinse: Immerse in rinse tank ensuring water flow is adequate and with good air agitation.

STEP FIVE: Blacking Solution ( Diluted 25%) Temperature above 20OC.

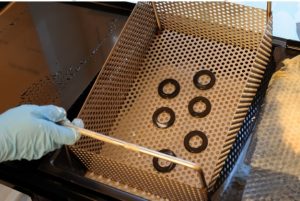

. Place basket or jig in tank.

. Soak for 10 seconds, remove and examine for even colour change if patchy remove component and return to tank 1 for further degreasing.

. If components are in a basket agitate periodically to ensure even contact with solution.

. Continue immersion until an even black colour is achieved, inspect periodically to ensure over blacking (Smutting) doesn’t occur anywhere from 40 – 90 seconds.

. Immediately a black appearance is achieved remove from tank

. Place basket or jig into tank six.

STEP SIX: Water Rinse: Immerse in rinse tank ensuring water flow is adequate and with good air agitation.

STEP SEVEN: Water Based Dewatering Fluid (Diluted 20%) Temperature 60OC + with air agitation or room temperature 20OC or above.

. Place basket or jig in tank.

. Soak for between 5 – 10 minutes. Remove and place on drain tray.

. Allow to air dry for minimum 5 minutes ( with excess oil in small holes etc. this can be removed after 5 minutes by GENTLE air blowing).